Metal framing system for drywall ceilings

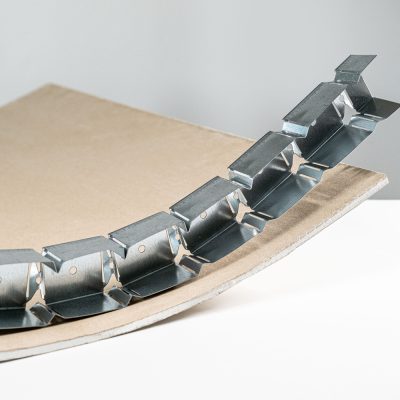

CobraKit Ceiling is the innovative framing system for the erection of curved plasterboard ceilings. The kit includes flexible tracks and studs, designed to adapt perfectly to the requirements of any architectural project. Selecting CobraKit Ceiling, the structures obtained will give superior mechanical strength combined with better acoustics, for guaranteed safety and comfort.

The Kit

Accessories

The CobraKit+ Ceiling package includes corner beads and edge beads that turn every angle contour into a visual feature. Attention to detail makes every surface a work of art, inviting and perfect.

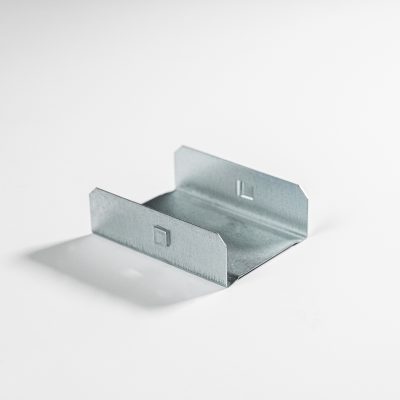

Straight connector

Creates a joint where profiles need to be extended beyond 3 metres in length.

Flexible metal corner bead

Mechanical protection and visual finish for corners adjoining curved surfaces.

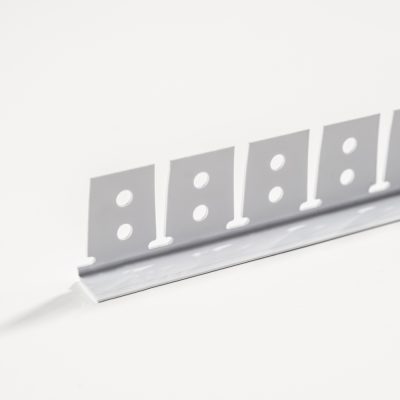

Flexible metal edge bead

Ideal for faultless finishing of edges on arches and vaults.

PVC corner bead

Mechanical protection and reinforcement for corners.

Installation?

Rest assured, it's easy!

Our profiles are the key element of the flexible systems we produce — acknowledged by top international distributors for their engineering excellence. With these smart components, creating curved plasterboard surfaces has never been so easy, and the installation procedure guarantees simplicity and precision.

1.

Marking and Shaping

- Mark out an accurate trace of the desired curve

- Shape the flexible profile for curved plasterboard by hand

2.

Aligning and Fixing

- Match the profile accurately to the curve marked

- Secure the metal profiles to the wall to ensure stability and precision

3.

Fitting and finishing

- Position the plasterboard sheets carefully on the framework of profiles

- Finish the curved surface with materials such as plaster, stone, or wood to achieve the desired final result.

Installation?

Rest assured, it's easy!

Our profiles are the key element of the flexible systems we produce — acknowledged by top international distributors for their engineering excellence. With these smart components, creating curved plasterboard surfaces has never been so easy, and the installation procedure guarantees simplicity and precision.

1.

Marking and Shaping

- Mark out an accurate trace of the desired curve

- Shape the flexible profile for curved plasterboard by hand

2.

Aligning and Fixing

- Match the profile accurately to the curve marked

- Secure the metal profiles to ensure stability and precision

3.

Fitting and finishing

- Position the plasterboard sheets carefully on the framework of profiles

- Finish the curved surface with materials such as plaster, stone, or wood to achieve the desired final result.